Summary

- Bacteria can strengthen lunar soil for making bricks on the moon, cutting down on costs.

- Bacteria produce calcium carbonate to help fill cracks in building materials.

- Adding guar bean extract to lunar material drastically increases brick strength.

Humanity has been reliant on bacteria for centuries. From fermentation and agriculture to making vaccines and genetic engineering, bacterial strains have found widespread industrial and lifestyle applications. In the near future, they could help make resilient bricks to build habitats on the Moon’s surface.

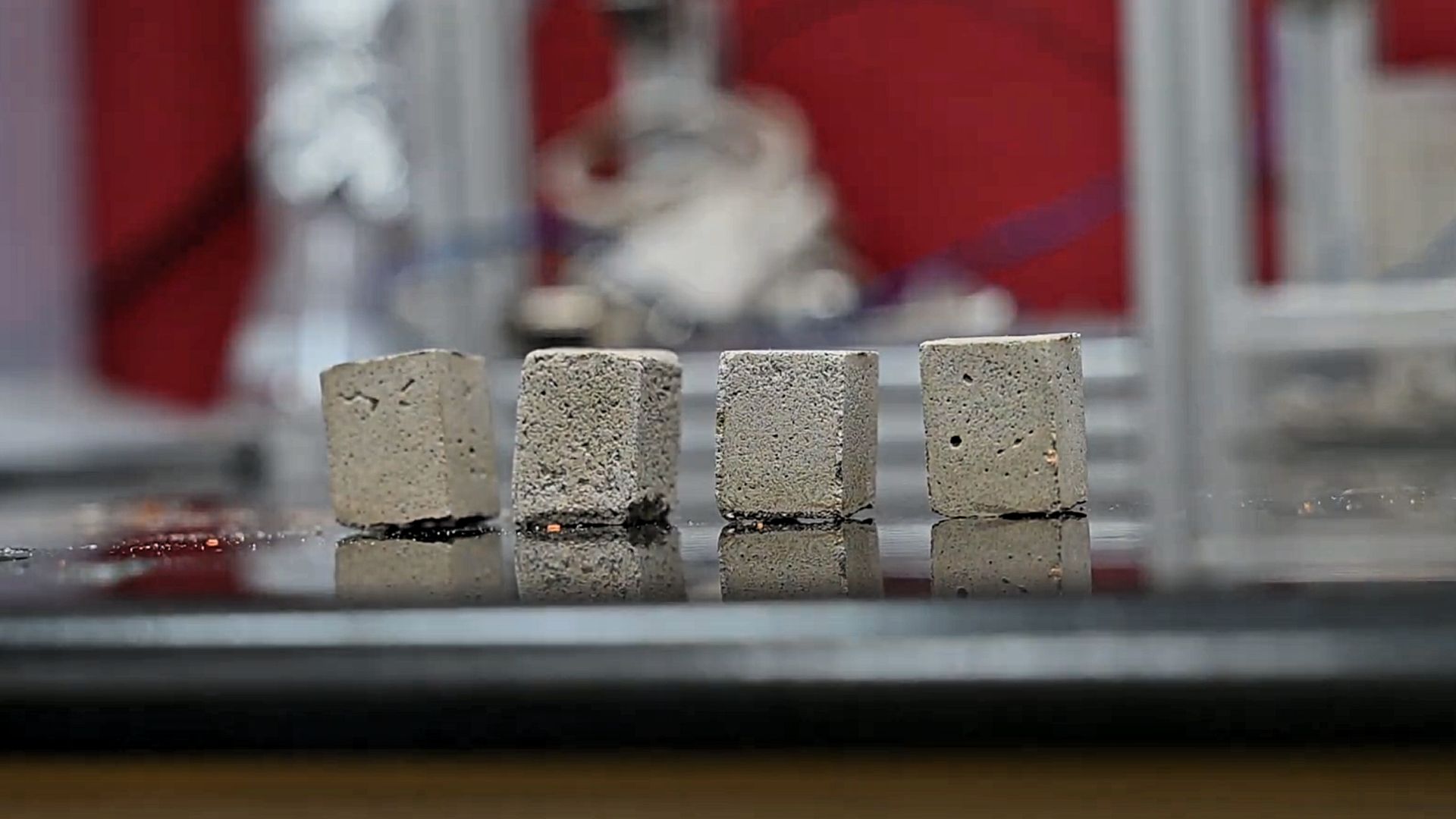

A team from India has developed a process reliant on bacteria to make stronger brick-like structures that can survive the harsh atmosphere of the moon. The approach is notable because it uses the lunar soil as the base material. Or in the words of NASA, In-Situ Resource Utilization (ISRU).

Solving a Critical Problem

One of the biggest challenges in the quest to build a settlement for humanity away from Earth is hauling all the material and equipment to an extraterrestrial body. According to Jennifer Edmunson, acting Program Manager for NASA’s Centennial Challenges, flying from Earth to the Moon can cost $1-1.12 million per kilogram of cargo.

To avoid that, NASA has actively explored in-situ ideas that can exploit the material locally available on the Moon, and even Mars. Building on that approach, a team of experts at the Indian Institute of Science (IISc) and the Indian Space Research Organization (ISRO) has developed a method to create what they refer to as “space bricks.”

The fundamental material used to make these bricks is lunar soil, combined with urine (as the source of urea) and guar bean, which is commonly grown in India and used to produce a food thickening powder called guar gum. This plant extract is used in powdered form as an additive to boost the material’s strength.

5 Reasons We Should Have a Base on the Moon

I vote for “Lunatic City” as the name for the first one.

The Secret Sauce

This is where the bacteria, a species named Sporosarcina pasteurii, come into the picture. It combines the calcium and urea in the building material to create calcium carbonate crystals that fill the cracks developing in the brick over time. “The final product obtained after a few days of incubation was found to possess significant strength and machinability,” says the team.

Broadly, the process is called bio-cementation, while the repair process is known as Microbially Induced Calcium Carbonate Precipitation (MICP). As per a paper published in the Frontiers journal, the bacterial repair can extend the functional lifespan of lunar bricks on the lunar surface.

Interestingly, this won’t be the first time that urine, or the aforementioned bacterial species, has appeared in space research. Experts at the University of Manchester created a material called AstroCrete that would essentially combine Martian soil with urine and astronaut blood. Interestingly, the biocomposite material turned out to be nearly as strong as concrete.

As far as the bacterial species goes, it’s a special one, and the strengthening properties of this bacterium have already been demonstrated with Earth-based projects. During a TED Talk, Magnus Larsson demonstrated an award-winning method of using bacteria to make solid dunes and prevent the expansion of the Sahara desert. Ginger Krieg Dosier, an assistant professor at the American University in Sharjah, has also developed a method to produce biobricks using the same bacterial species, urine, and sand.

The core role of Sporosarcina pasteurii is to produce calcium carbonate, which is deemed extremely compatible with the constituents of concrete. When cracks appear in concrete, the bacterial material triggers the formation of calcium carbonate to fill the cracks and seal them.

In a separate paper published in the PLOS Journal, the team tested another bacterial species named Bacillus velezensis. It is approximately ten times more affordable, and during lab tests, it produced twice the amount of the crack-filling material.

The Power of Beans

Calcium supplements are recommended by doctors worldwide to boost the strength and growth of bones. In nature, calcium’s role in minerals isn’t too different. The teams at IISc and IIT began their work on space bricks with bacteria, urea, and calcium. The base material was lunar soil simulant (LSS), which is rich in silicon, carbon, oxygen, and aluminum.

The guar gum, extracted from guar beans, plays a crucial role in making the construction material due to its role as a polymer additive. In fact, as per the research paper published in the Ceramics International journal, the organic gum increased the brick’s strength by nearly six times.

“In independent experiments performed under flask conditions, it was observed that guar gum accelerated both bacterial growth and MICP related activity,” says the research paper. Another impressive aspect of these space bricks is that they are quite machinable and allow free-form shaping to suit the construction needs.

A simple lathe is all that’s needed to shape the material, which opens the doors for easily making interlocked designs and reducing the hassle of specialized molds. The team is now looking forward to making larger bricks and scaling up the manufacturing process beyond labs. The focus ahead will be on making the bricks stronger so that they can brush off seismic activity on the lunar surface. Yes, the moon is full of surprises, and ‘moonquakes’ are one of them.

Interestingly, the same team is also working on a similar bacteria-driven strategy for making bricks using the Martian soil. The real challenge, of course, will be transporting the machinery that can harvest the lunar regolith and turn it into space bricks. Let’s hope the Artemis mission brings back the glory days of mankind on the moon and opens the doors for long-term settlements.